TSMC's Expansion Sparks Cultural Clashes and Worker Treatment in Arizona

Taiwan Semiconductor Manufacturing Company (TSMC), a titan in the chipmaking industry and the largest company in Taiwan, is facing serious backlash over its treatment of workers at its new plants in Arizona. As part of the CHIPS Act, TSMC received billions from the U.S. to shift some production stateside. However, the company's notoriously intense work culture has not translated well with American engineers.

In Taiwan, TSMC is revered, with workers enduring 12-hour days and harsh management as a badge of honor. This work ethic is deeply embedded, with the company founder famously emphasizing rapid response times to machinery breakdowns, regardless of the hour. American engineers, trained in Taiwan for the upcoming Arizona operations, were shocked by these expectations. The high-pressure, all-priority environment led to significant dissatisfaction, with many quitting during or after their training phase.

The Arizona facilities are lagging behind schedule, and the work culture has not adjusted well on American soil. Reports of mismanagement include engineers being tasked with menial jobs like trash collection and faking test results to meet unrealistic goals. Cultural misunderstandings have further strained relations, with American and Taiwanese workers harboring mutual resentments.

Despite these issues, TSMC is unlikely to slow down, buoyed by substantial CHIPS Act funding and the premium prices it can command for American-made chips. However, the need for a better workplace environment remains critical for future success and employee retention. For more insights, check out the full story at Rest of World.

Why This Matters to Us:

In the transportation and logistics industry, keeping an eye on major manufacturing shifts like TSMC’s expansion into Arizona is crucial because it can hint at broader economic shifts and opportunities for logistics providers. The fact that TSMC, a key player in the semiconductor industry, is expanding in the U.S. signals a growing trend of reshoring manufacturing operations, which could increase the demand for logistics services domestically.

Our Take:

The TSMC situation underscores the potential hiccups when global companies enter local markets with vastly different work cultures. It’s a lesson on the importance of cultural adaptability - not just for manufacturing giants but for any business, including those in logistics, planning to expand or collaborate internationally. This could be a prompt for businesses like yours to consider how to manage cultural integration and employee satisfaction effectively as part of your strategic planning, especially when you're navigating international partnerships or expansions.

It's all about learning from the missteps of others and being one step ahead in managing your growth challenges.

The Biden administration has committed up to $6.4 billion to help Samsung Electronics set up a major computer chip manufacturing hub in Texas.

Taiwan Semiconductor Manufacturing Company (TSMC) is making a significant move by bringing its most advanced technology to America, aligning with U.S. President Joe Biden’s goals for a secure tech supply chain.

Taiwan Semiconductor Manufacturing Co. (TSMC), a global leader in semiconductor fabrication, is set to receive a significant boost in the U.S. with up to $6.6 billion in funding from the U.S. government.

A massive 7.2-magnitude earthquake rocked Taiwan's eastern coast last Wednesday, causing not only tragic loss of life but also significant ripples in the semiconductor industry.

Taiwan's biggest quake since 1999 could jolt the semiconductor supply chain across Asia.

Taiwan Semiconductor Manufacturing Company (TSMC) recently inaugurated its inaugural chip plant in Japan, a move aimed at diversifying its supply chains amidst escalating trade tensions between the U.S. and China.

Taiwan Semiconductor Manufacturing Company (TSMC) reported a third-quarter profit of 211 billion New Taiwan dollars ($6.69 billion), which marked a significant decline in profit due to weak demand for consumer electronics.

In a conversation with Lotta Danielsson, Vice President of the U.S.-Taiwan Business Council and editor of the report "U.S., Taiwan, and Semiconductors: A Critical Supply Chain Partnership," Taiwan's significant role in the semiconductor supply chain is discussed.

A study by the Semiconductor Industry Association (SIA) and Oxford Economics predicts that the U.S. semiconductor industry will face a shortage of around 67,000 workers by 2030.

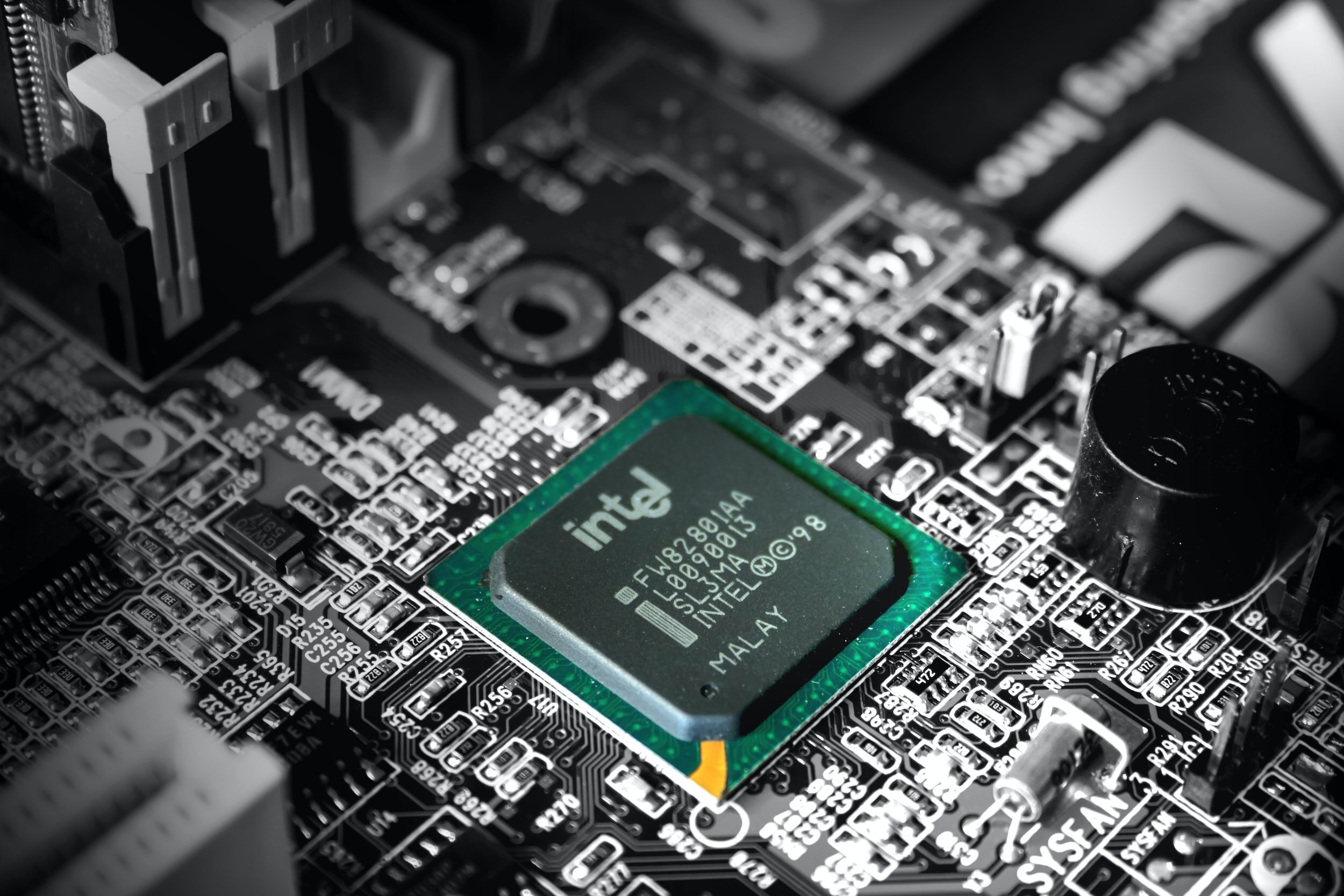

The microchip industry plays a pivotal role in various key sectors of the global economy, from computing and telecommunications to military and healthcare.

The U.S. and EU are taking steps to lessen Asia's stronghold on the global semiconductor market. With the shift of semiconductor manufacturing operations to major Asian countries, the U.S. and Europe have faced challenges in maintaining competitiveness.

Intel is investing $4.6 billion in a new assembly and testing facility in Poland and expanding its investment in a semiconductor fabrication plant in Germany, totaling approximately $33 billion.

The Department of Commerce has announced a funding opportunity and application process for large semiconductor supply chain projects, providing a boost to semiconductor companies.

Micron Technology Inc. has announced a significant investment of $602 million in its chip-packaging plant in China, despite recent restrictions imposed by the Chinese government on the use of its semiconductors.

Various governments worldwide have introduced semiconductor strategies worth billions of dollars to address supply chain disruptions and secure chip supplies.

A recent report highlights the success of reshoring initiatives, leading companies to scramble to find manufacturing operations in the United States and Mexico.

The Semiconductor Industry Association, a major US industry group, wants clear rules from the Biden administration regarding investment restrictions for chip companies in China.

South Korea is aligning with the United States and Japan, which could lead to greater cooperation and coordination among these countries in the development and production of advanced semiconductor technologies.

In the race to fully transition to green energy, investments are rampant on both sides of the Atlantic Ocean to integrate electric vehicles and other sources of clean energy.

By pooling their purchasing power, companies can negotiate better prices for critical resources used in electric batteries.

The Chicago Transit Authority is adjusting the strategy of operating electric buses throughtout the city, especially during the year’s coldest months.

Economic historian Chris Miller, a professor at Tufts, is tackling the challenges associated with the semiconductor industry with their new book, "Chip War: The Fight for the World's Most Critical Technology”.

The US semiconductor industry is starting to stir as the $52 billion in subsidies from the CHIPS act sits on the table.

Semiconductors are used in a wide variety of electronic components in modern vehicles, including engine control units, infotainment systems, and safety features such as airbags and anti-lock brakes.

There has been a lot of chum in the water over China’s veiled threats to invade Taiwan - much to the United States’ dismay.

While China still controls nearly 60% of the world‘s rare earth mining operations, the United States is looking to close the gap over the next decade.

There is a global battle over precious metals such as lithium, cobalt, nickel, and copper because they are critical components used in the manufacturing of batteries for electric vehicles, renewable energy systems, and electronic devices.

Countries around the world are scrambling to mine critical rare earth minerals because they are essential components in the production of a wide range of clean energy technologies, including wind turbines, solar panels, and electric vehicles.

On Friday, TSMC's shares in Taipei took a significant hit, dropping by 6.7% following their first-quarter earnings report.